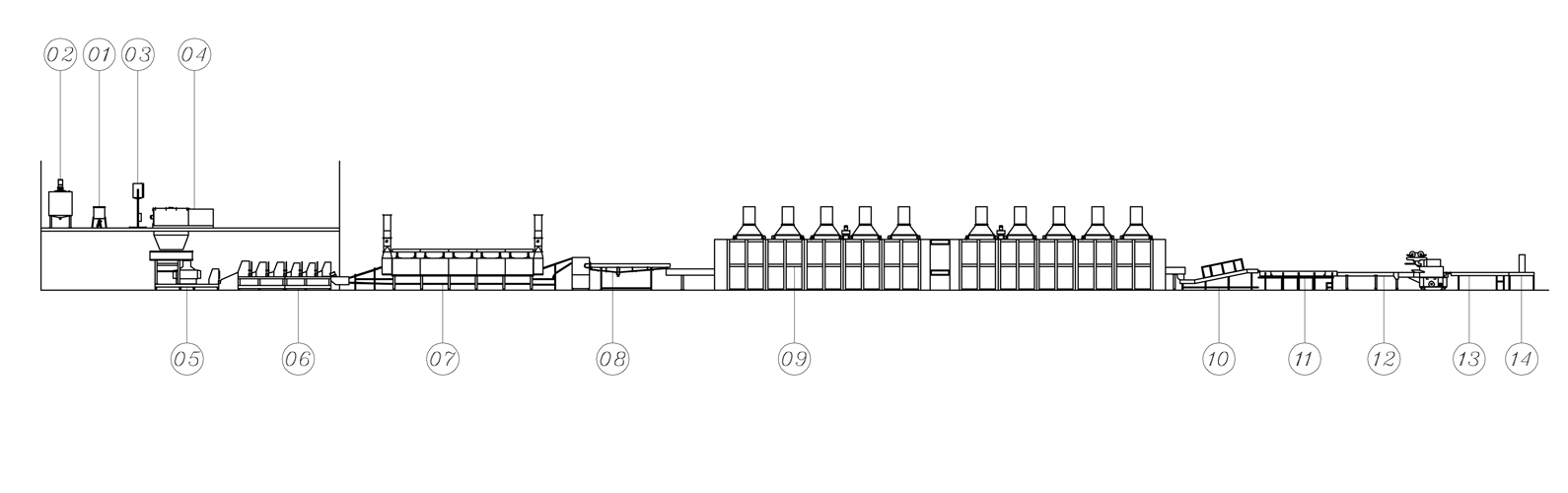

Automatic Dried Noodle (Ramen) Production Line

LTD-600

Production Process

Specification

Noodle Weight: 65~70 grams

Production Capacity: 100,000 pcs / 8 hours

Production Parameters

- Plant Space Required: 80m(L) x 12m(W) x 7m(H)

(office and wharehouse for raw materials and finished products excluded) - Power Consumption: 130Kw (main production line)

- Steam Boiler: 3,000kg/hour

- Working Pressure: 10kg/cm²

- Water (soft water) Consumption: 4,500kg/hour

- Operator Required: About 5 persons (Main Production Line)

Features

- With highly customized production process and parameters by PLC adjusted system, you will be able to produce your own ramen noodles with ultimate features to cater to various customers in the global market.

Machines

(1) Additives Agitating Tank

This noodle production equipment will accelerate the dissolution rate of those ingredients based on your noodle recipe.

(2) Soda Water Storage Tank

This noodle production device comes with a single-axis agitator. The water inlet is on top of the tank, and the outlet is at the bottom. Salt, soda and other seasoning ingredients can be added pro rata according to the water scale. Round shape with optional double-layer insulation, this device can include a cold water circulation loop inside based on client's required customization. Cold water can be introduced to lower water temperature and enhance the quality of dough.

(3) Water Tank with Level Controller

The round tank is equipped with an automatic flow device for filling water. This device is automatic, with precise metering, uniform filling, without liquid remnant.

(4) Mixer

A horizontal, two-axis designing, device features inverter speed adjustment, PLC, human-machine-interface (HMI) operation, and self-diagnosis. Adopting a thorough-agitating technique, the precision equipment simulates the traditional noodle-making master's process, including mixing, kneading, drawing, rest, massaging, in order to make noodles natural, tasty, and firm.

(5) Material Feeding & Compounding Machine

The feeding rotary shaft surface has coating Teflon to prevent dough from sticking and easy to be cleaned after noodle production process. A positioning device is mounted to ensure steady and smooth feeding. This machine consists of three pressure rollers. After pieces of dough are pressed into two layers by two rollers, they are then formed into a blank by the third roller. Material is fed against the analog sensor, under whose control compounding and stretching are synchronous and through which the thickness of the noodles in the dough sheet arc can be adjusted even.

(6) Stretching Machine

This noodle machine comprises five or six pairs of stretching rollers designed in independent transmission for ratio and synchronous control. Through the continuous dough stretching with sheeting rollers, the dough quality will be highly improved and the thickness dough sheet can be equally adjusted to the perfect rolling ratio for noodle production.

(7) Steaming Machine

Temperature control is conducted by adjusting the steam temperature at the valve. Steaming speed, temperature and time adjustment are very convenient. Temperature inside the steam carriage is distributed uniformly.

(8) Cutting & Seasoning Machine

The high-pressure dewatering fan and the uniquely designed air knife can remove soup residue to decrease unnecessary water and residue entering the high-temperature pan along with the noodle pieces and to reduce the degenerating speed of the oil.

(9) Drying Machine

We can design such noodle making machine with multiple steps of drying conditions by raditors and turbo blowers to establish a perfect control of temperature and flow with steady delivery speed to reduce the drying time and water content, enhancing the noodle quality.

(10) Cooling Machine

This noodle production equipment can be customized to adopt cooling fan or blower designing. Cool air is circulated by the cooling fan or mutiple blowers to exhaust hot air promptly and effectively.

(11) Bag Noodle Conveyor

An intelligent speed-adjusting design automatically controls the conveyor's speed according to the noodle production speed.

(12) Pillow Type Bag Packing Machine

The speed of packing machine here can be adjusted based on the former noodle production equipment and then transmit the packaged noodle into the following device.

(13) Product Conveyor

The conveyor will transmit those instant noodles after packaging machines.

(14) Carton Sealing Machine

This is the semi-auto sealing machine to help factory operators to seal the packed instant noodle into cartons more efficiently.

Contact Us

Contact Us