Machines

Machine Introduction

Automatic Two-Side Sealing with Shrink Tunnel

This packaging machine will adjust the line speed based on the ratio of the former tray or carton packing machine and process the film sealing and shrinkage of wrapped cup noodles.

Roller Conveyor

This conveyor can be used for the transmission of wrapped cup noodles in trays or cartons for further process.

Drying Machine

We can design such noodle making machine with multiple steps of drying conditions by raditors and turbo blowers to establish a perfect control of temperature and flow with steady delivery speed to reduce the drying time and water content, enhancing the noodle quality.

Cooling Machine

This noodle production equipment can be customized to adopt cooling fan or blower designing. Cool air is circulated by the cooling fan or mutiple blowers to exhaust hot air promptly and effectively.

Frying Machine

The bottom of the frying machine is designed with a number of oil inlets to significantly adjust temperature in steps in order to meet the needs of different products.

Both ends of the machine are equipped with oil-removing devices like air knife (and blower) and oil scraper to effectively reduce the oil of noodles and the oil consumption rate of the equipment effectively and thereby cut back the production cost.

Continuous Breaking Machine

The noodle machine will break the cut noodle strip into chips.

Material Feeder & Mixer I

The feeding conveyor can transmit the noodle chips into the mixer for mixing.

Mixer II

The production equipment here will mix the noodle chips again before the transmission to the forming machine.

Syrup Preparation Tank

This production equipment is for the usage of seasoning preparation and process.

Material Feeding & Forming Machine

This noodle production equipment will transmit the mixed noodle chips to the forming machine.

Forming Machine

This noodle machine will shape those mixed noodle chips into noodle snacks in different forming.

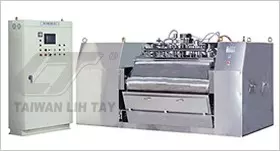

Continuous Drying Machine

This production equipment will dry and dehydrate the noodle snacks after forming the shape of noodle chips.

Cooling Machine

The production device is equiped with fans or blowers to cool down the noodle snacks to the required temperature before packaging machines.

Vertical Weighing Filling Sealing Machine

This packaging machine will measure the weight of noodle snacks and pack based on the requirements.

Dough Sheet Aging Conveyor

This production equipment will ripen the dough sheet after compounding machine.

Hanging Machine

This production equipment will transmit the noodle stick to the drying chamber.

Noodle Stick Arrangement Machine

This production equipment will recut the noodle sticks after cutting machine for suitable stick length of drying.

Automatic Bowl / Cup Input Device

This packaging machine will place the cup stably and smoothly to the cup clip device.

Automatic Rotary Bowl / Cup Placing Device

This cup loading equipment will move back and forth from the cup clip device and the cup sucking rotary device for the placement of cup onto the noodle cake.

Automatic Distributor

This automatic pouch dispenser is very easy to adjust the speed & pouch size with memory function to switch quickly between pouches with different specifications.

Automatic Placing Lid Device

This packaging machine will place the lid onto cup and partial sealing device.

Rejection Output Device

This production equipment will reject the disqualified bowl/cup noodle.

Automatic Sealing Lid Device

This packaging machine will seal the bowl/cup lid twice and inspect the sealing.

Contact Us

Contact Us