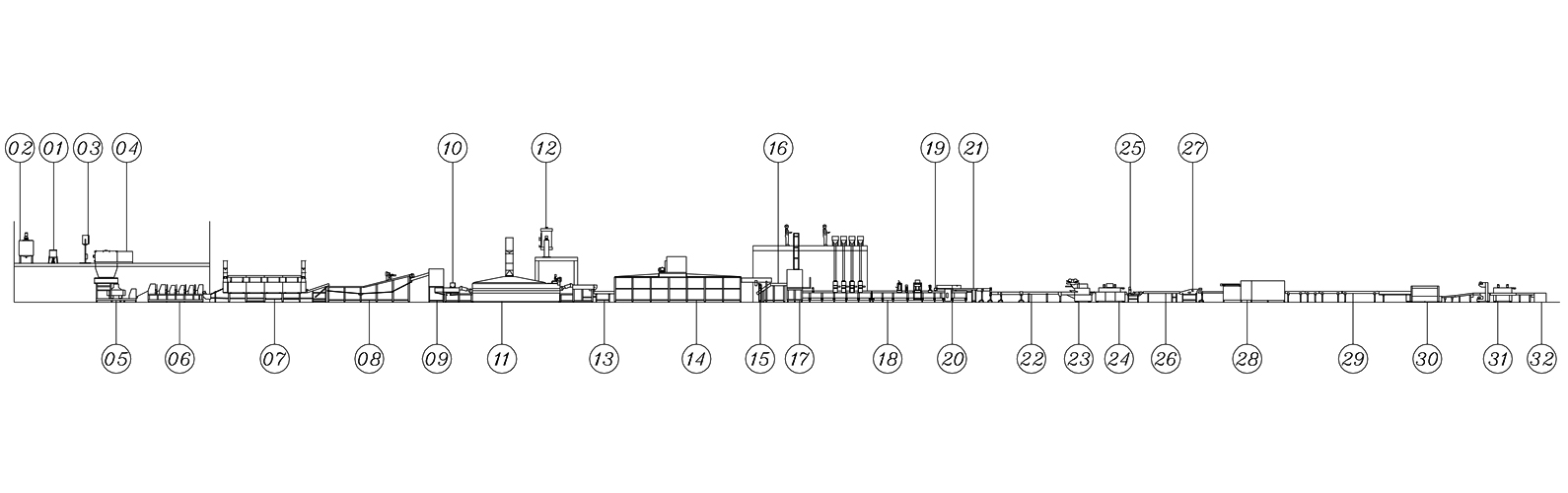

Automatic Bowl (Cup) Instant Noodle Production Line

LTC-500

Production Process

Specification

Noodle Weight: 50~55 grams

Production Capacity: 120~420 cups/minute

Production Parameters

- Plant Space Required: 132m(L) x 12m(W) x 7m(H)

(office and wharehouse for raw materials and finished products are excluded) - Power Consumption: 230Kw (main production line)

- Steam Boiler: 3,000kg/hour

- Working Pressure: 10kg/cm²

- Water (soft water) Consumption: 5,000kg/hour

- Frying Oil Consumption: 2,000kg / 8 hours

- Operator Required: 18 persons

(a) About 8 persons before packing process

(b) About 10 persons for packing operation

Features

- With Servo motor or Cam driven automatic bowl or cup filling and sealing machine, the greatly efficient performance of container noodle production at your instant noodle plant can be ensured.

Machines

(1) Additives Agitating Tank

This noodle production equipment will accelerate the dissolution rate of those ingredients based on your noodle recipe.

(2) Soda Water Storage Tank

This noodle production device comes with a single-axis agitator. The water inlet is on top of the tank, and the outlet is at the bottom. Salt, soda and other seasoning ingredients can be added pro rata according to the water scale. Round shape with optional double-layer insulation, this device can include a cold water circulation loop inside based on client's required customization. Cold water can be introduced to lower water temperature and enhance the quality of dough.

(3) Water Tank with Level Controller

The round tank is equipped with an automatic flow device for filling water. This device is automatic, with precise metering, uniform filling, without liquid remnant.

(4) Mixer

A horizontal, two-axis designing, device features inverter speed adjustment, PLC, human-machine-interface (HMI) operation, and self-diagnosis. Adopting a thorough-agitating technique, the precision equipment simulates the traditional noodle-making master's process, including mixing, kneading, drawing, rest, massaging, in order to make noodles natural, tasty, and firm.

(5) Material Feeding & Compounding Machine

The feeding rotary shaft surface has coating Teflon to prevent dough from sticking and easy to be cleaned after noodle production process. A positioning device is mounted to ensure steady and smooth feeding. This machine consists of three pressure rollers. After pieces of dough are pressed into two layers by two rollers, they are then formed into a blank by the third roller. Material is fed against the analog sensor, under whose control compounding and stretching are synchronous and through which the thickness of the noodles in the dough sheet arc can be adjusted even.

(6) Stretching Machine

This noodle machine comprises five or six pairs of stretching rollers designed in independent transmission for ratio and synchronous control. Through the continuous dough stretching with sheeting rollers, the dough quality will be highly improved and the thickness dough sheet can be equally adjusted to the perfect rolling ratio for noodle production.

(7) Cube Type Steaming Machine

The thermal control of such continuous steamer is conducted by adjusting the steam temperature via the steam equal-distribution system. Steaming speed, temperature, and time adjustment are very convenient for your fried or dried noodle production process. The temperature inside the steaming conveyor is distributed uniformly.

(8) Seasoning Dipping & Aging Machine

The production equipment can diversify the noodle flavors and ripen the noodle strip before proportional cutting process.

(9) Stretching & Cutting Machine

This production equipment can be synchronously controlled through the simple and user-friendly operation interface to adjust the noodle length and dimension.

(10) Noodle Arrangement Device

This noodle production equipment can adjust the noodle shape based on the required production parameter before frying process.

(11) Frying Machine

The bottom of the frying machine is designed with a number of oil inlets to significantly adjust temperature in several steps to meet the needs of different noodle production. Both ends of the machine are equipped with oil-removing devices like air knife or blower and oil scraper to effectively reduce the oil content of instant noodles and the oil consumption rate of such continuous fryer effectively and thereby cut back the production cost.

(12) Heat Exchanger & Oil Storage Tank (Optional)

Such noodle production equipment will be made of SUS304 stainless steel required for the hygienic noodle production process.

(13) Noodle Distribution Conveyor I

This conveyor will rearrange the noodle cakes in sequence and ensure the continuous distribution to the cooling machine.

(14) Cooling Machine

This noodle production equipment adopts air circulation cooling design. Cool air is filtered and provided by the blower to ensure cooling hygienically. With the highly efficient blower to discharge humid and hot air promptly, the excellent cooling effect can be ensured.

(15) Noodle Distribution Conveyor II

This conveyor will rearrange the noodle cakes in sequence and ensure the continuous distribution to the sporadic cup noodle packing machine.

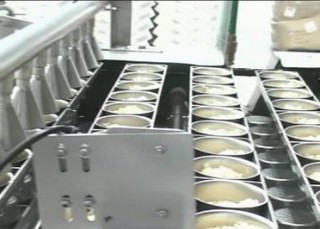

(16) Sporadic Cup Noodle Packing Machine_Ⅰ

This packaging equipment will place the cup stably and smoothly to the cup clip device.

(17) Sporadic Cup Noodle Packing Machine_Ⅱ

This packaging equipment will move back and forth from the cup clip device and the cup sucking rotary device.

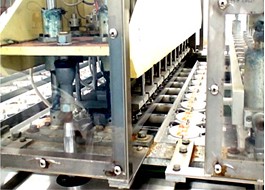

(18) Sporadic Cup Noodle Packing Machine_Ⅲ

This packaging machine will place the lid onto cup and seal.

(19) Sporadic Cup Noodle Packing Machine_Ⅳ

This packaging machine will seal the cup lip and inspect.

(20) Sporadic Cup Noodle Packing Machine_Ⅴ

This production equipment will inspect and reject the disqualified cup noodle.

(21) Cup Noodle Conveyor

This packaging machine will adjust the line speed based on the ratio of the former production equipment and transmit the cup noodle to the following packing machine.

(22) Packing Converyor

This packaging machine will adjust the line speed based on the ratio of the former production equipment and transmit the cup noodle to the following pillow type cup noodle packing machine.

(23) Pillow Type Cup Packing Machine

The speed of this packing machine here can be adjusted based on the former noodle production equipment and then transmit the packaged noodle into the following device.

(24) Shrinkage Chamber

This packaging machine will adjust the line speed based on the ratio of the former pillow type cu packing machine and process the film shrinkage of cup noodle.

(25) Weight & Metal Inspection Machine

This production equipment will measure the weight and inspect the foil of the finished cup noodles for rejection of unqualified cup noodles.

(26) Product Conveyor

The conveyor will transmit those instant noodles after packaging machines.

(27) Cup Standing Machine

This production equipment will rotate the cup noodles in the right direction based on the packing machines hereafter.

(28) Sleeve Packing Machine

The packaging machine is specially customized based on the requirements of different cup, bowl, or container noodles.

(29) Dviding Machine

This packaging machine will adjust the line speed based on the ratio of the previous production equipment and divide the cup noodles into different rows before transmission to the following packing machine.

(30) Tray Packing Machine

This packaging machine will adjust the line speed based on the ratio of the former production equipment and wrap the packed cup noodles into trays or cartons automatically.

(31) Automatic Two-Side Sealing with Shrink Tunnel

This packaging machine will adjust the line speed based on the ratio of the former tray or carton packing machine and process the film sealing and shrinkage of wrapped cup noodles.

(32) Roller Conveyor

This conveyor can be used for the transmission of wrapped cup noodles in trays or cartons for further process.

Contact Us

Contact Us